Perfect GePro

Production planning

Provides tools for the organization and planning of the production, starting from order analysis, organization and management of activities, dividing materials by family types, etc.

Perfect GePro uses all the data inserted on Perfect ERP management in order to provide useful tools to organize the production job.

The program includes:

• The automatic order separation in the correct sequence of the work phases.

• The time estimate necessary for every resource.

• The Orders portfolio management.

• The Batches management and creation.

• The production calendar.

• The production monitoring specifics for the cut (Perfect Monit), the tempering and for all the other resources.

• The requirements management that with stock’s data allows to know if the materials needed to complete an activity are available or if is essential to wait a supplier delivery.

• A tools series thought to interact with Perfect Cut.

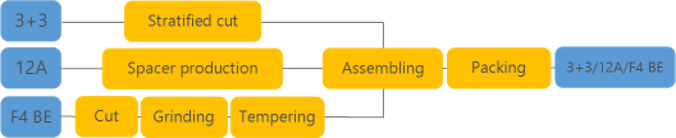

From office to the production

From office to the production

Every sale order is analized and automatically divided on work phases. So the production can work in tune with the office, but in a different environment that allows to organize data as needed.

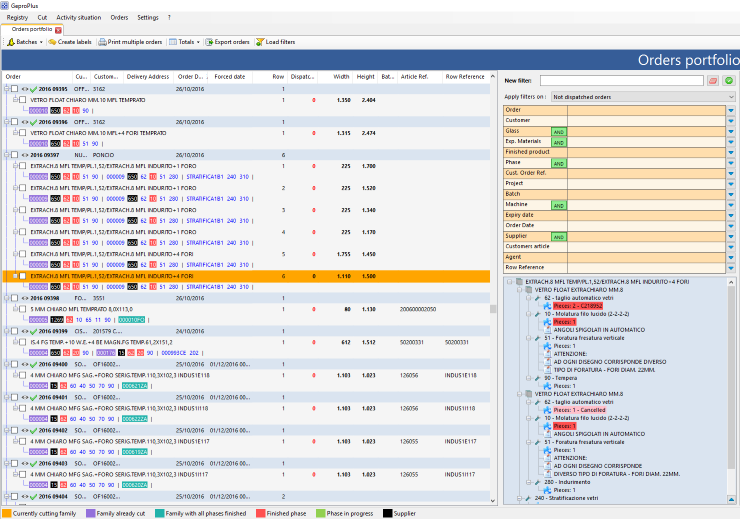

Orders portfolio – A lot of informations, maximum control

Orders portfolio – A lot of informations, maximum control

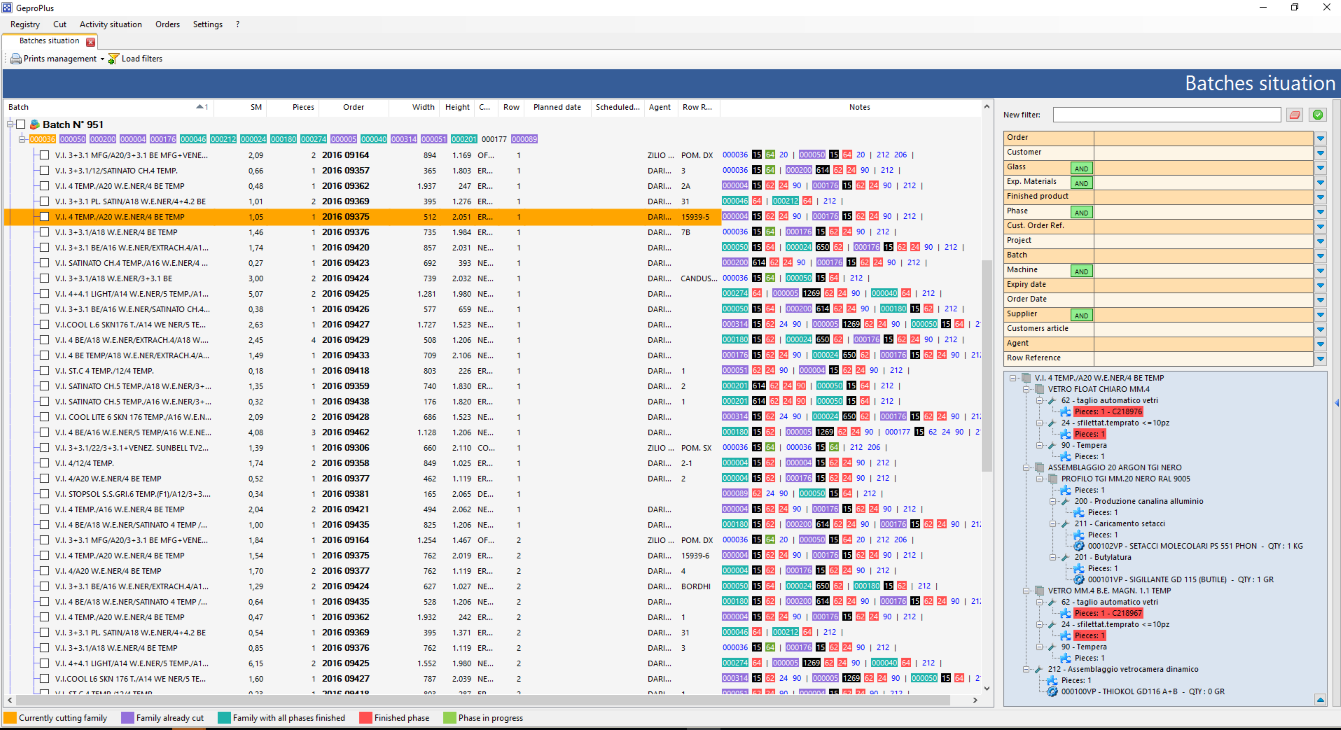

The orders portfolio contains all the scheduled orders on Perfect ERP dispatched or not.

In the interface are visualized all the row divided by sale order and it’s possible to filter and sort data in the most appropriate way (Perfect GePro filters management).

For each order row is indicated families and near by the related machining phases.

In this form it’s possible to apply filters. Clicking on the row of an order, appears on display in the bottom right, the article deposit.

In the deposit, the red highlighted elements indicates pieces of completed machining phases.

The possible operations to make on the display are:

- The batch creation selecting orders to merge.

- The labels creation selecting one or many material row. So it’s possible to export to Perfect Label all the necessary informations to print the selected articles labels, customizing them according to article or customer.

- The multiple print on selected orders to get: office copy, packaging copy, spacers and laminated glasses copy, production copy and original copy.

- The visualization on all the orders or the filtered ones, of the total quantity of finished and machined pieces on all the machinings or on a chosen one.

- The order exportation in html format.

- The filters selection to apply on the window.

Moreover, clicking with the right button of the mouse, on the head of an order many options like print, visualization, window settings etc. are available.

Organize the activities

Organize the activities

The orders data are divided in work phases available on orders Portfolio form.

The form provides different tools to organize orders row on the disired way.

It’s possible:

- To use filters management system to get exactly the desired informations

- To regroup the orders creating batches

- To check the batches status

- To see the orders rows divided by material family and to select the ones to insert on projects to export on Perfect Cut

- To see for each cutting resource, Perfect Cut projects divided by family

Batches creation

Once that the work organization has been decided, it is possible to regroup rows and to create batches. From that moment the production can work with a job program well defined and developed with criteria. The created batches can be visualizied, filtered and printed through Batches status form.

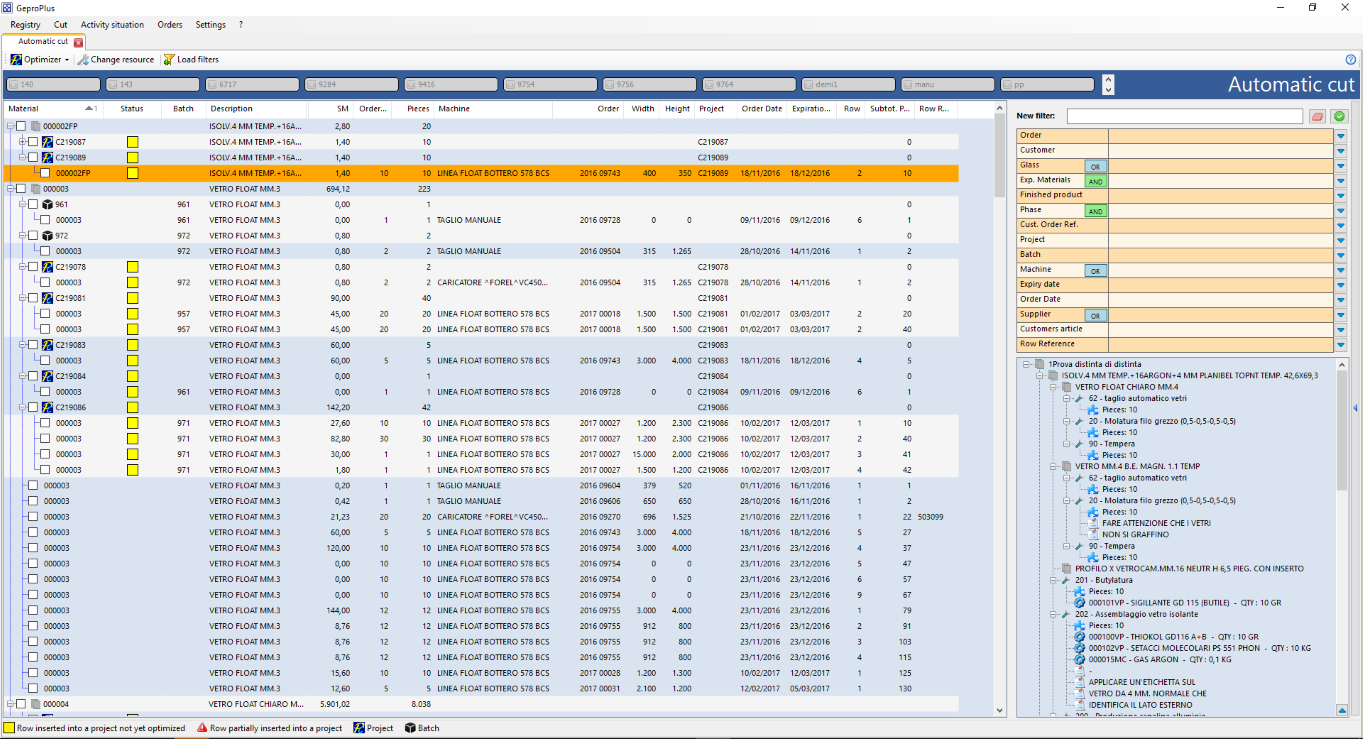

Material family

It is possible to see all the not dispatched orders rows regrouped by material family in the form called automatic cut, that provides a perfect prospective of work to send on production in order to reduce material wastefulness and logistics problems.

It is possible to control and manage orders rows,batches and create projects to export on Perfect Cut ready to be sent to NC.

There are many possibilities to export rows, selecting:

- Orders single families (not inserted yet in projects and batches).

- Batches single rows.

- Entire batches.

- Single families and batches rows.

The projects contain only articles with the same family. The project informations are saved and after the creation it’s possible to remove or add pieces to complete the last sheet directly interacting with Perfect Cut.

On rows that are not part of a project, it is possible to change the set cutting resource.